Meet our single ply roofing experts

Our people make us who we are

FiberTite® synthetic single ply membranes feature a reinforced polyester knit fabric, coated with a proprietary compound, utilising ELVALOY™ Ketone Ethylene Ester (KEE) as the principle polymer in the hybrid vinyl alloy coating.

All FiberTite® Roofing Membranes are constructed using high tenacity/heavy weight yarns to create a base fabric reinforcement to provide superior puncture, tensile and tear resistance properties. The base polyester fabrics are primed with a unique and proprietary adhesive coat that lays the foundation to physically bond the KEE coatings to the ‘fibre’, in order to maximise seam strength and overall membrane performance.

The ELVALOY™ Ketone Ethylene Ester (KEE) polymer content is embedded within our FiberTite® roofing membranes. This exceptional feature not only imparts flexibility but also renders our products highly resistant to chemicals and the relentless onslaught of UV light. With KEE as the foundation, our roofing systems proudly brave the harshest environmental challenges, ensuring lasting protection for your building.

What truly differentiates this product is our unwavering commitment to excellence. MOY FiberTite® Roof Systems are fortified with proven fiber reinforcement, meticulously arranged in a “tite” pattern, crafting one of the industry’s most robust base fabrics. This meticulous design results in unmatched puncture and tear resistance, setting new standards for durability and reliability for Synthetic membranes.

FiberTite® is available with a fleeced-backing for adhered applications, along with standard plain membrane for mechanically fixed systems.

Single ply roofing systems are perfect for cost-effective construction projects. Lightweight and quick to install, our synthetic membrane products are durable with long life expectancies with systems to match current fire regulations. Membranes can be utilised in both new build and refurbishment projects across many market sectors within flat roofing.

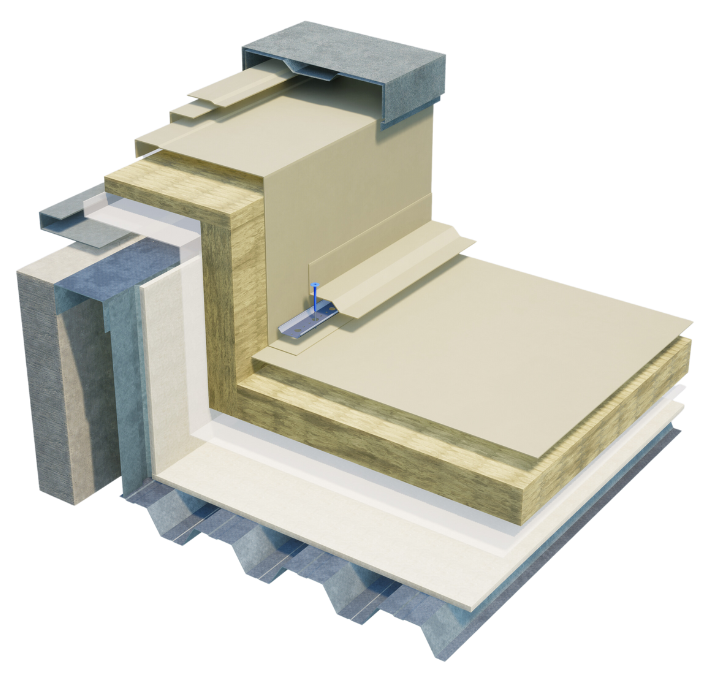

Uppermost layer of the system which is applied over the substrate usually as the final exposed waterproofing layer. This will be either the FiberTite® for mechanically fastened systems, or the FiberTite® FB Fleece-backed membrane for adhered systems. There may be a need for additional layers over the FiberTite waterproofing membrane, depending on the ultimate use of the roof area. Where Green/Blue roofs are to be installed, or where the roof is to be used as a trafficked area, such as balconies, terraces or under plant & equipment, appropriate protection and or drainage & filtration layer(s) should be installed.

Thermal insulation is an essential component within a warm roof system. Its purpose is to control and maintain the temperature of the building below. It’s important to ensure a sufficient thickness of insulation is installed in order to meet the requirements of the appropriate Building Regulations and local legislation. Other considerations are critical when selecting the type of material used as a thermal insulant, such as its compressive strength and loading capacity, acoustic properties, fire performance and compatibility with the waterproofing system.

Purpose of the air and vapour control layer is to reduce or control the passage of air and moisture vapour passing from within the building, up through the roofing system, potentially causing risk of interstitial condensation within layers of the roof construction or allowing increased levels of air leakage.

Where applicable, depending on the type of AVCL used, an appropriate primer may be necessary prior to the application of the AVCL over the roof deck.

The structural roof deck spans the structural frame of the building to provide a continuous support for the roofing system and ultimately what the roof is attached to. This may be in the form of a profiled steel, profiled aluminium, concrete or timber deck. All designed to accommodate all anticipated design loadings.

Colour

Off White. Options available dependent on Specification

Finish

Smooth

Material

FiberTite® is a reinforced polyester knit fabric, coated with a proprietary compound, utilising ELVALOY™ Ketone Ethylene Ester (KEE) as the principle polymer in the hybrid vinyl alloy coating.

Shape

rectangular

Length

various roll sizes, dependent on membrane type.

Width

various roll sizes, dependent on membrane type.

Warranty Description

Moy offer duration versatility in warranty dependant of the specification.

Base fabric is the heaviest in the industry providing superior puncture resistance, excellent fatigue strength, chemical resistance and cold flexibility at temperatures down to - 20°C.

FiberTite® is available with extended system warranties and a service life in excess of 25 years.

British Board of Agrément (BBA) certified, CE marked, Environmental Product Declaration (EPD) inclusion, Factory Mutual Certified options.

TS 1187 BROOF Regional Fire Certification (consult Moy for guidance).

UV protection, multiple colour options and available with High Solar Reflective Index Rating (SRI). Evaluated by the Cool Roof Rating Council (CRRC).

Declaration of performance

Declaration of performance

For a full list of technical downloads available from MOY see our Technical Downloads page

All Technical Downloads