Meet our bitumen roofing experts

Our people make us who we are

Paraflex ARD/S and ARD/HS are SBS modified bitumen polymer waterproofing membranes intended for all waterproofing applications including; Flat Roofs, Terraces, Podiums, Car Parks and Bridge Decks, Tunnels, Foundations and Underground Structures.

The Paraflex range of waterproofing membranes is FM approved, may be used in new build and refurbishment applications and are suitable for applications in low temperature conditions. Paraflex remains flexible at low temperatures and exhibits high resistance to thermal stress.

Reinforced Bituminous Membrane (RBM) which is commonly referred to as felt, still remains one of the most widely specified and installed forms of flat roof waterproofing for both new build and refurbishment projects across many market sectors within flat roofing.

There is a broad range of polymer modified felts to choose from to suit different applications.

RBM can accommodate extreme stresses from thermal movement and wind loading, whilst withstanding a higher degree of construction and maintenance traffic, making it an ideal choice for many projects.

Combining bitumen with additives Styrene Butadiene Styrene (SBS) alters the characteristics and performance of the membrane.

The addition of different carriers such as glass fibres, polyester or a blend of both produces a waterproof material on a roll that is easy to install, very strong, and low in cost.

Many developments and improvements have been made over the years, including development of both the bitumen compound, modification of polymers and the reinforcement materials used, originating with materials such as tar paper or asbestos, progressing to safer, higher-quality materials such as glass fibre or more recently polyester.

Polyester is probably one of the biggest improvements for RBM, making membranes extremely resilient, durable and long lasting. Improving the resistance to tearing and impact along with its resistance to withstand foot traffic.

The Paraflex SBS bitumen compound’s special formulation ensures high mechanical performance, cold flexibility at temperatures down to -25°C and excellent fatigue strength. The membrane is manufactured with a mineral slate or mineral stone granule coating to the upper surface of the membrane, in various colours, offering UV protection and slip resistance. The lower face is coated with Termotene® fusible film which aids unrolling and facilitates torch bonding to various substrates.

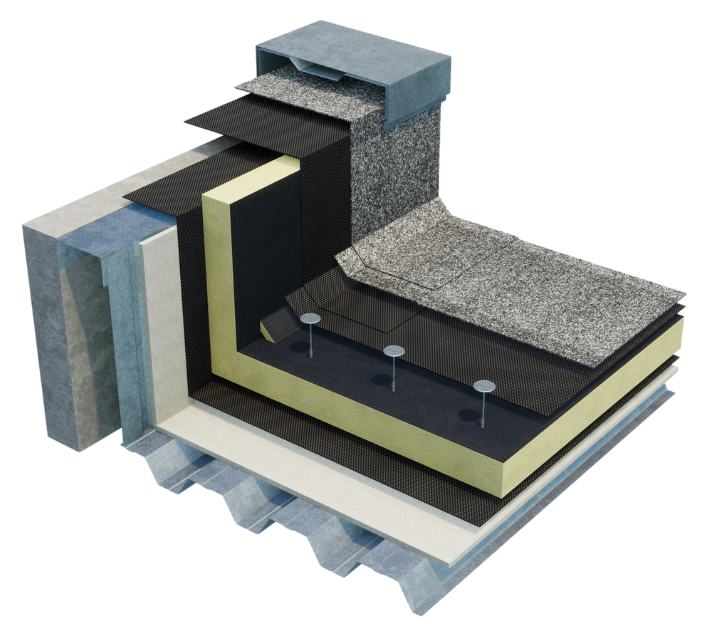

Uppermost layer of reinforced bitumen membrane which is applied over the base layer as the final exposed waterproofing layer. This will be either the Paraflex ARD/S or the Paraflex ARD/HS cap sheet, with a mineral slate or mineral stone granule finish to provide UV protection.

First layer of reinforced bitumen membrane, installed in the built-up waterproofing system. Paraflex NT3 or Paraflex NT4 will be utilised as appropriate.

Thermal insulation is an essential component within a warm roof system. Its purpose is to control and maintain the temperature of the building below. It’s important to ensure a sufficient thickness of insulation is installed in order to meet the requirements of the appropriate Building Regulations and local legislation. Other considerations are critical when selecting the type of material used as a thermal insulant, such as its compressive strength and loading capacity, acoustic properties, fire performance and compatibility with the waterproofing system.

Purpose of the air and vapour control layer is to reduce or control the passage of air and moisture vapour passing from within the building, up through the roofing system, potentially causing risk of interstitial condensation within layers of the roof construction or allowing increased levels of air leakage.

Where applicable an appropriate primer will usually be required prior to the application of a bituminous AVCL over the roof deck.

The structural roof deck spans the structural frame of the building to provide a continuous support for the roofing system and ultimately what the roof is attached to. This may be in the form of a profiled steel, profiled aluminium, concrete or timber deck. All designed to accommodate all anticipated design loadings.

Colour

Multiple Options available dependent on Specification

Finish

Granular surface

Material

Paraflex special formulation combines the best characteristics of SBS modified bitumen, reinforced with a synthetic non-woven continuous filament polyester fabric.

Shape

Rectangular

Length

1000 mm

Width

1000 mm

Warranty Description

Moy offer duration versatility in warranty dependant of the specification.

Extremely resilient, durable and long lasting making Paraflex resistant to tearing and impact and as a result capable of withstanding foot traffic. Excellent resistance to punctures and UV degradation.

Paraflex is available with extended system warranties and a service life in excess of 25 years.

British Board of Agrément (BBA) certified, Irish Agrément (NSAI) certified, CE marked, Environmental Product Declaration (EPD) inclusion, Factory Mutual Certified

TS 1187 BROOF Regional Fire Certification (consult Moy for guidance).

Paraflex membranes contain no asbestos, tar or other dangerous (red list) substances.

Paraflex System options and multiple colour options, including Highly Solar Reflective Index Rating (SRI) and skid inhibiting surface finishes.

Declaration of performance

Declaration of performance

Declaration of performance

Declaration of performance

Declaration of performance

Declaration of performance

For a full list of technical downloads available from MOY see our Technical Downloads page

All Technical Downloads