Meet our hot melt roofing experts

Our people make us who we are

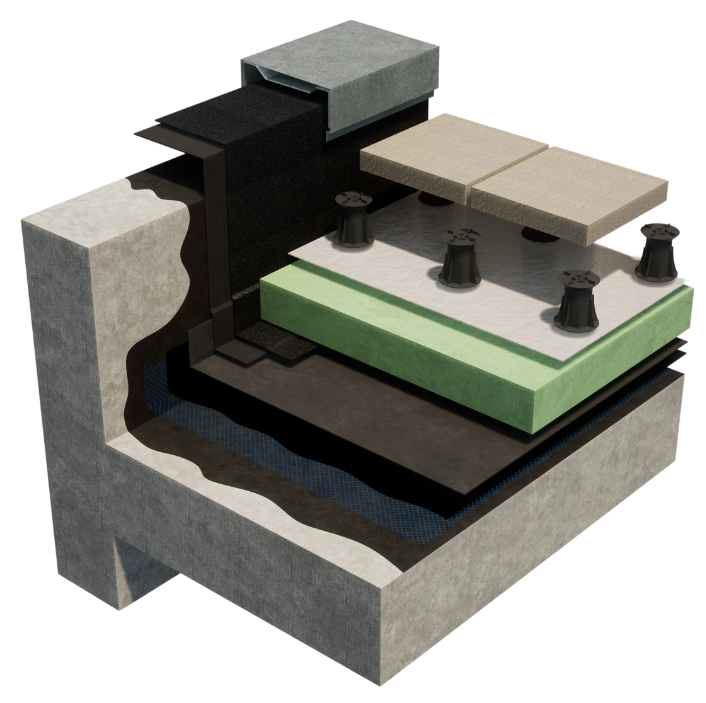

Paro-Melt® is a 2nd generation hot melt structural waterproofing system used in inverted roof applications.

The Paro-Melt® elastomeric self-healing polymer modified bitumen compound, is used with a robust SBS bitumen protection membrane, to give a tough monolithic but flexible roof system. Full immersion of our MOY distinctive blue reinforcement fabric mesh ensures the correct amount of hot melt compound is being installed. The Paro-Melt compound is supplied in blocks and is pourable when heated to a temperature of between 150°C and 180°C. This must be carried out using a thermostatically controlled bitumen boiler complete with regulator, to avoid overheating and potential degradation of the product.

Designed primarily for use over concrete in inverted roof applications such as podium decks, green roofs, car parks, terraces and balconies, the full Paro-Melt® system includes a wide range of thermal insulation boards, specifically designed (closed cell) for use in inverted applications, where they are installed above the waterproofing layer and exposed to the effects of rainfall. Water flow reducing layers (WFRL) and other accessories complete the system.

Installed on flat and zero-pitched roofs (defined in BS EN 6229: 2018), over suitable types of structural decks, pre-treated with Paro-Melt® Holt Melt Primer to ensure a full bond and prevent water tracking.

A roof incorporating the Paro-Melt® system will be unrestricted under the National Building Regulations when used in a protected or inverted application and when covered with an appropriate surface finish, including listed inorganic coverings in the ‘Annex of Commission Decision 2000/553/EC’.

See BBA Agrément Certificate No 20/5745 for details.

Uppermost layer of the inverted roof system, forming the finished and trafficked surface of the roof. Depending on use and required functionality this is usually in the form of concrete paving slabs on paving support pads, well-rounded stone ballast, extensive green, intensive green or bio-diverse roof finishes. All should provide the appropriate ballast weight in order to withstand wind uplift forces and mitigate risk of floatation of the insulation.

A vapour permeable layer, lapped and sealed, is installed over the insulation to restrict the flow of water in an inverted roof system. This reduces the ‘cooling effect’ of rainwater on the insulation, reducing the correction values required in thermal calculations for insulation on inverted roofs in turn reducing insulation thicknesses. The WFRL also acts as a filter to prevent small fines or particles being washed in between and below the insulation, potentially damaging the waterproofing or blocking drainage.

Thermal insulation is an essential component within any inverted warm roof system. Its purpose is to control and maintain the temperature of the building below. It’s important to ensure a sufficient thickness of insulation is installed in order to meet the requirements of the appropriate Building Regulations and local legislation. Other considerations are critical when selecting the type of material used as a thermal insulant, especially when used in an inverted application are, its suitability certified in inverted applications where it is above the primary waterproofing layer and exposed to the passage of rainwater through the roof. In addition, due to the additional weight of ballast that will be imposed on the roofing system and the likelihood of increased levels of pedestrian access and foot traffic, the compressive strength and loading capacity of the insulation must also be checked. Fire performance and overall compatibility with the waterproofing system is also a key consideration when selecting the insulation.

The Paro-Melt® Protection Membrane is a polyester reinforced, SBS elastomeric modified bituminous waterproofing membrane with anti-root additive, finished on both upper and lower surfaces with fine sand to aid full adhesion into the Paro-Melt® Hot Melt Compound. The protection membrane is rolled into the Paro-Melt® Hot Melt Compound in a pour and roll application method.

Paro-Melt® Hot Melt is an elastomeric polymer modified bitumen mastic, designed for use as the structural waterproofing compound in a hot melt waterproofing system. The compound is heated and applied in a poured application simultaneously with Moy’s distinctive blue Paro-Melt® Reinforcement Mesh, immersing the specially designed glass-fibre fabric mesh. This governs the amount of compound and its flow rate to ensure an even and consistent coverage rate, maintaining the specified film thickness of the waterproofing.

Paro-Melt® Hot Melt Primer will be required over the roof deck, prior to the application of the Paro-Melt® waterproofing system to ensure full adhesion to the substrate is achieved.

The structural roof deck spans the structural frame of the building to provide a continuous support for the roofing system and ultimately what the roof is attached to. For inverted hot melt applications, due to imposed loadings for such roofs, this will usually be in the form of pre-cast concrete or in situ concrete cast over a profiled steel liner. It is critical the deck is designed to accommodate the additional design loadings expected of this roof type.

Colour

Black

Finish

Smooth

Material

Polymer modified bitumen

Shape

Formless

Length

Bespoke

Width

Bespoke

Delivery Form

24kg blocks wrapped in silicone cardboard

Warranty Description

Moy offer duration versatility in warranty dependant of the specification.

Excellent fatigue strength, durable and extremely long-lasting, making Paro-Melt® resistant to tearing and impact and ideal for buried heavily trafficked applications. Cold flexibility at temperatures down to –16°C.

Reduced application processes resulting in quicker application compared to 1st generation hot melt systems.

The Paro-Melt® Reinforcement Mesh governs the amount of compound and its flow rate to ensure an even and consistent coverage rate, maintaining the specified film thickness.

Fully bonded to the substrate means no risk of water tracking

Paro-Melt® is available with extended system warranties and a service design life of the structure.

British Board of Agrément (BBA) certified, CE marked.

BROOF (t4) Fire Certification Classed ‘Unrestricted’ – Deemed to Satisfy (consult Moy for guidance or refer to BBA Agrément Certificate No 20/5745).

Compatible with range of surface finishes, including Podium finishes & Green Roofs.

Paro-Melt® contains no asbestos, tar or other dangerous (red list) substances.

Declaration of performance

Declaration of performance

For a full list of technical downloads available from MOY see our Technical Downloads page

All Technical Downloads